AtoCap team visits GMP manufacturing facility in Valencia

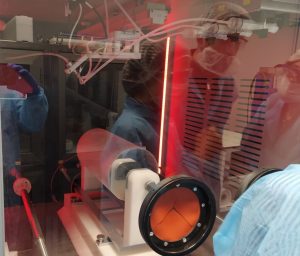

Just before Christmas, Ann Savell, Eleanor Stride and Jenny Rohn inspected Bioinicia’s Electrospraying Assisted by Pressurized Gas (EAPG) industrial demonstration facility in Valencia.

Photograph: Jennifer Rohn

Standard electrospray techniques enable the processing of only a few mL per hour. The EAPG technique employed by Bioinicia uses high voltage and pneumatic pressure to achieve high-throughput microencapsulation in a large-scale, pharma-grade GMP and ISO certified plant.

The demonstration facility can produce 1–3 kg of dry power per hour, but may be scaled up to enable the production of tens of kilograms of encapsulated product per hour. Bioinicia is to build the world’s first industrial plant for electrospray microencapsulation of bioactive ingredients—a necessary step for the scale-up and commercialization of AtoCap’s innovative drug delivery system.

In 2017, Bioinicia was the world’s first electrospinning/electrospraying contract manufacturer to be awarded GMP (pharmaceutical) certification, enabling the manufacture of electrospun/electrosprayed products for pharmaceutical applications.

Photograph: Ann Savell